seawater intakes

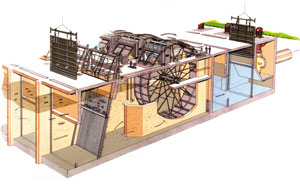

For seawater intakes our hydro mechanical equipment encounters vertical intake pumps and stop logs, as well as coarse and fine screening.

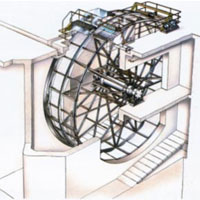

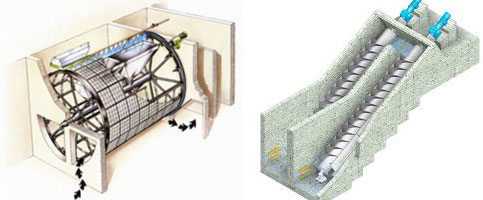

Coarse Screening

For coarse screening, our solutions encompass cable operated and back racked bar screens with scalability in size, operation and automation. Integrated trash racks and embedded solutions are also the other point of competence with our coarse screening machines.

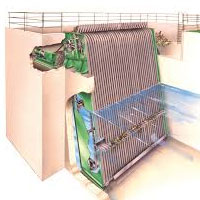

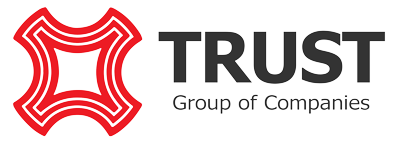

Fine Screening

In fine screening, we provide travelling band screens, drum and micro drum screens with a diversity of capacities that are compliant to different intake environments. These screening solutions are well prepared to manage the jellyfish attacks of Persian Gulf and such kind of complexities. Embedded solutions are also known as the other flexibility factor that makes our solutions compliant with any intake concrete.

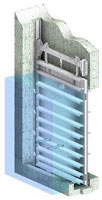

With Screen

As with screens, our stoplog solutions are compatible with versatile capacities, concrete environment, water resistance and operation demands.

Vertical intake pumps

For pumps, our high capacity vertical intake pumps can be provided with different differentiation heads and material. Our pumps can stream up to 20 m3/min from intense water intakes to secondary treatment plants.

According to material, we are capable of providing our solutions with any correspondent material that satisfy complex and intense demands for corrosion resistance and protection.

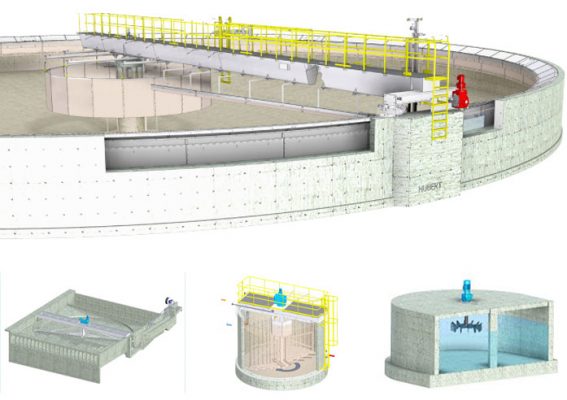

Nowadays water is more important globally than ever before. In some regions like the Middle East, water shortage has already reached dangerous levels. More specifically, there is sever water scarcity in Iran. Despite Iran having the largest gas and oil reserves in the world, climate change and the overuse of water in traditional agriculture is affecting the nation. Iran is already undersized of water resources which is worrying for the future of the country.

Water desalination technologies have been used for more than 50 years in the Middle East and have become the main solution to reducing water shortage. The region has got almost half of the World’s desalination capacity, with the Persian Gulf having the largest share.

Seawater desalination needs careful design and adequate testing from the very early stages of the project. Any desalination system requires attentive analysis from various aspects. For example, testing the source of water to conclude what kind of pre-filtering and solutions is required to protect membrane desalination systems.

There are many challenges involving desalination projects. It can have a significantly negative implication on the environment. In seawater desalination, one of the major issues is the amount of discharge of salt and its effect on the ecosystems. This is the primary concern especially for the Persian Gulf as there are considerable number of desalination plants around the region and it is an enclosed and small size sea.

Therefore it is crucial to work with world’s best leaders in desalination technology and solution providers from the early stages of the project lifecycle to have the most efficient and cost effective system in the long run.

With fast growing number of the water desalination plants in Iran, the demand for filters and membrane is rising abruptly. As the quality and cost are the two main factors of producing pure water, TRUST is recently investing in developing manufacturing line for water filtration and membrane in Iran.

We are working closely with universities to develop our water treatment process know-how as well as cooperating with world water treatment leaders to provide our customers with the best membranes that are designed to meet their unique requirements.